Description

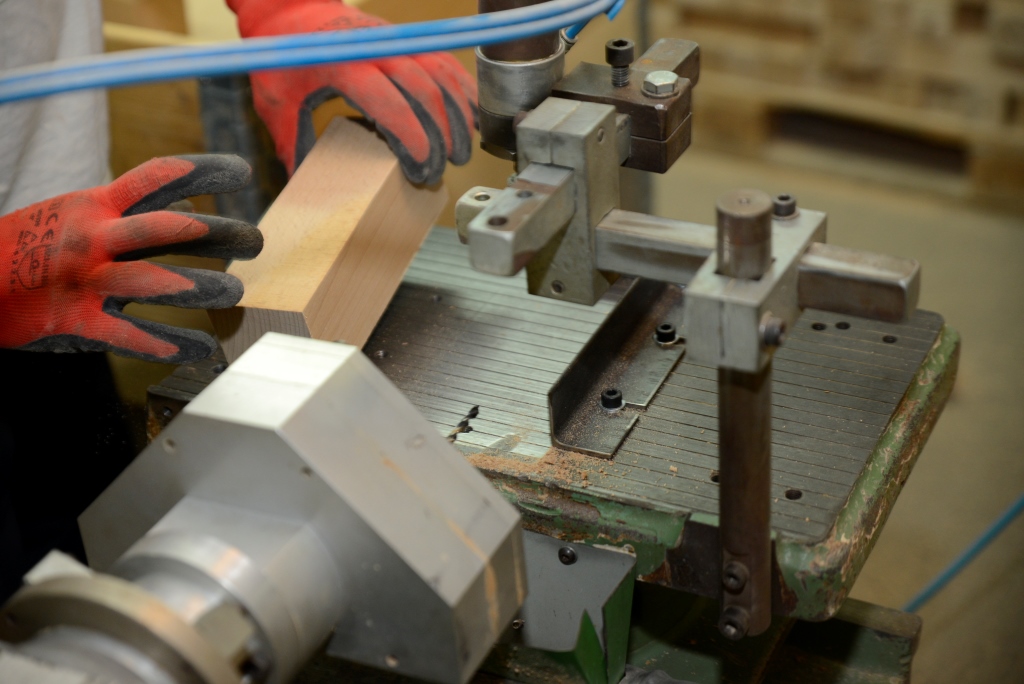

For the purpose of obtaining the final product of good quality, it is necessary for the wood to be hydrothermally processed in certain production stages. Our company’s technology is based on a well-rounded production process, from cutting raw logs, through drying, to the final processing on contemporary machines, so as finishing according to the stipulated standards. Moisture removal in the dryers with over-200m3 chamber capacity requires regulation and controlling the parameters in order to improve mechanical and physical properties of wood, and, accordingly, the final product of better quality. Increasingly greater demands and merchantability inspired us to formulate the manufacture of our products carefully and correctly. The optimal distribution of machines and workers leads towards improving the efficiency and increasing the range of serial production. In the production plant, there are contemporary machines, CNC mills, longitudinal joint lines are there to facilitate our work and provide serial production. The finishing of our products is based on applying non-toxic substances, we use water-based varnishes exclusively, adhesives without formaldehyde, and application of bio oils. “Standard Furniture Serbia” tries to approach the buyer as a customer the best way it can, by advancing permanently, investing in contemporary equipment, improving, with its contemporary and modern design, with every product being genuinely functional. Watch the video!